Affordable and accurate laser engraving

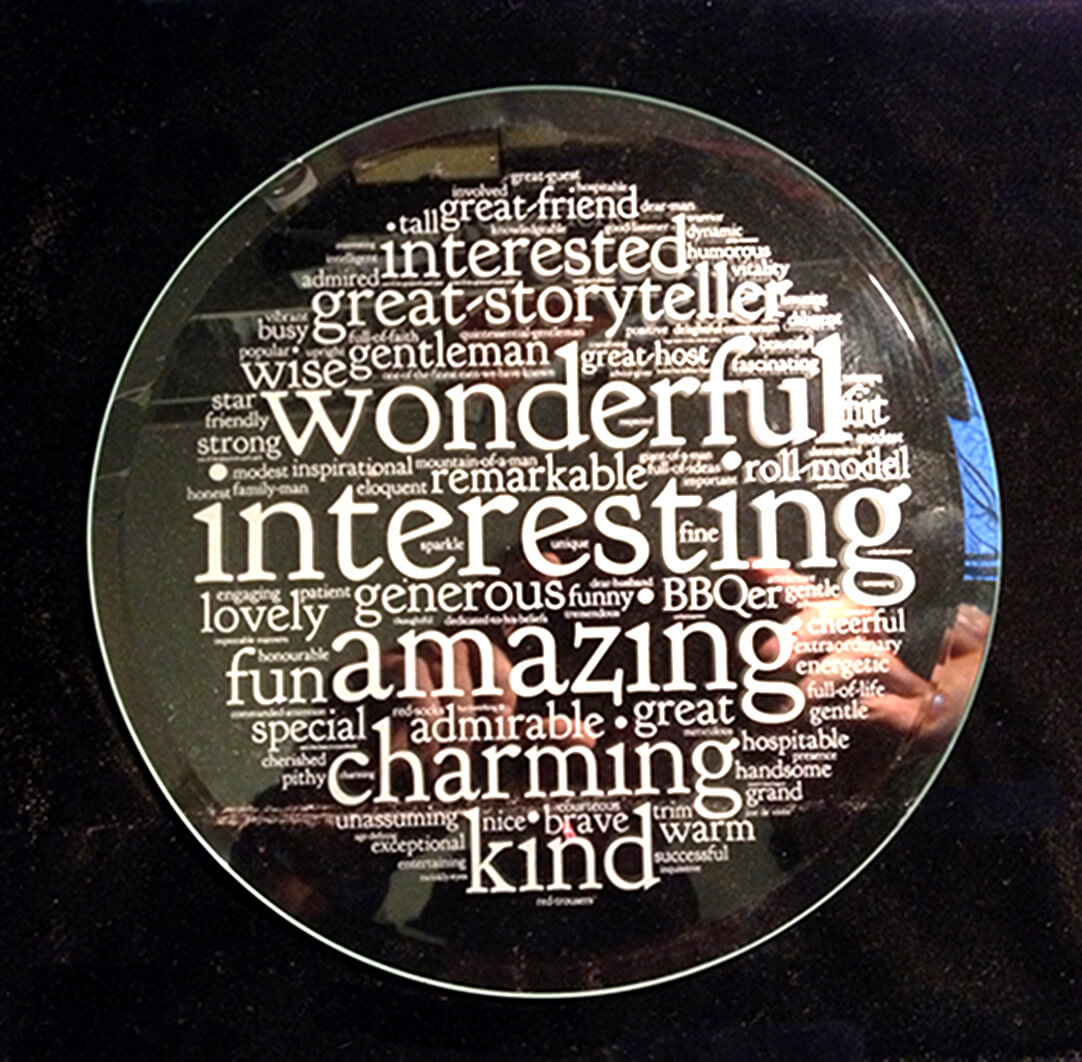

This plaque was created initially by producing artwork using proprietary editing software such as CorelDraw, Photoshop or Illustrator. The finished artwork is then printed out onto an acetate. The acetate is then placed upon the top of a specially designed film that reacts to Ultra Violet light. Basically, the film hardens when bathed in the light. The part that does not harden is where the black text is on the film. The film can then be jet washed with water to wash away the portion of the film that remains soft i.e. where the text resides. The film is then dried and stuck to the glass. Any remaining glass areas not covered by the film can be masked off with tape. The glass can now be sandblasted and the film cleaned off when complete. This is the result.

This wooden plaque was created by the use of a CNC machine with a Tungsten cutter rotating at 16000RPM. A film was affixed to the surface of the wooden plaque prior to cutting to protect the surface at a later stage. Once the cutting process had been completed then black paint has been applied into the trough created by the letter creation. The film protects the areas outside of the letters from paint contamination. In other words, it stops the paint getting onto the surface outside of the lettering. In order to protect the surface from all weathers, we then apply a generous coating of varnish.

This bottle lock for wine is made from stainless steel. The engraving is carried out using a CNC machine with a faceted diamond cutter installed. The diamond is rotated at approximately 10000RPM so that the facets of the diamond remove a fraction of the steel during the engraving process. This enhances the cut to make the finished engraving stand out.

This heart shaped wooden chopping board has been engraved using a Laser. The laser burns the surface of the wood to produce a blackened finish. The power output from the laser can be adjusted to produce any depth of cut into the surface. This is important with a chopping board as you want the cut depth to be shallow or crumbs will fill the lettering and it will be difficult to keep clean. One important point is that wood from different trees creates different colour effect when burned with a laser. They do not all come out black.

Metal can be engraved in a number of ways. But shown here, we are using a CNC machine with a facetted diamond driven in rotation at 15000RPM. This cuts into the surface of the metal plate that we have cut into shape to fit the wooden backing plate.

Laminated plastic comes in a variety of different colours. We cut away the top layer to reveal the substrate layer. It is used for Gravemarkers, Instrument panels and plaques.

This Stainless Steel Gauge has been engraved using a 30W Fibre Laser. By adjusting the output power and speed the surface can be made to turn black as in the photo. This style of engraving is permanent and very precise. As with other types of engraving any font style can be used providing we ha the font on our computer. Many additional fonts can be obtained through Google (Other search engines are available) many are free.

This is engraved using a CO2 laser that burns through a surface layer of gold plastic to reveal the underside substrate which is black in colour. There are many colours of material available such as blue, yellow, green, white, gold, silver, bronze, red and more, all with a substrate of black. The underlying substrate can also be different colours and there are some funky colours available such as sparkling silver etc.

To create a truly unique and special gift visit us by appointment, just to take a look, be inspired or organise a commission.

We use the very latest laser cutting and laser engraving machines

If we give you a price, we’ll stick to it, with no hidden extras

even if you just want to come and get some ideas.